In today’s harsh climate, roof waterproofing repair is critical for maintaining the integrity of both residential and commercial buildings. With factors such as heavy rain, high humidity, and extreme temperatures impacting roofing systems, proper waterproofing is essential to prevent leaks, moisture invasion, and potential structural damage. Homeowners and commercial property managers alike must understand that effective waterproofing helps extend the life of the roof while maintaining its aesthetic appeal and functional performance. Advanced materials like waterproof roof tape, butyl rubber sealants, and liquid-applied membranes provide chemical bonds that reduce the risk of leaks, ensuring a tight building envelope that prevents moisture from penetrating. In addition, the proper installation of waterproofing systems contributes to a warranty for roof repairs and replacement, providing peace of mind in the face of environmental challenges. As moisture, mildew, and wind continue to take their toll on roofing systems, maintaining a roof becomes a proactive measure rather than a reactive expense. This article outlines the detailed process involved in roof waterproofing repair along with essential preparation, execution, troubleshooting, and maintenance strategies.

Transitioning from the importance of waterproofing, the following sections will dive into quality evaluation, preparatory steps, techniques, and long-term sustainability practices that can significantly reduce repair costs and increase protection.

Effective roof waterproofing repair begins with a thorough understanding of the overall objectives and crucial benefits that a waterproofed roof delivers. Defining these aspects serves as the foundation for planning and executing repairs that meet both aesthetic and structural requirements. Waterproofing a roof not only prevents water intrusion but also protects the underlying structure from the harsh effects of mildew, corrosion, and temperature fluctuations. This protection is essential, as a compromised roof can lead to interior damages, from peeling ceiling paint to ruined structural elements potentially caused by water seepage.

Roof waterproofing repair objectives generally focus on achieving seamless adhesion of repair materials to the roof substrate, ensuring that chemicals like butyl rubber, silicone sealants, and polymer-based coatings form a durable, continuous barrier. Key objectives include: – Maintaining an uninterrupted barrier against moisture, reducing the risk of dampness and roof leak repair complications. – Enhancing the building envelope with a robust waterproofing system that can withstand adverse environmental conditions such as rain, wind, and high humidity. – Improving the roof’s chemical bond with the substrate to ensure that treatments like roof waterproofing tape and liquid-applied membranes remain effective over time. – Integrating materials that have been proven via peer-reviewed studies to promote adhesion and elasticity, ensuring that future impacts from temperature fluctuations or physical abrasions do not compromise the waterproof integrity.

Defining clear objectives also helps in prioritizing which areas of a roof require urgent attention versus those that can be maintained with routine care. The use of high-quality building materials, including waterproof roof tape, cement-based coatings, and butyl rubber, helps realize these objectives and guarantees long-lasting performance of the repair.

The benefits of roof waterproofing extend far beyond basic leak prevention. First, a properly waterproofed roof reduces the development of mold and mildew, which not only improves indoor air quality but also supports long-term health for building occupants. Secondly, it enhances energy efficiency, as moisture intrusion can disrupt insulation efficacy, leading to increased heating and cooling costs. Third, a sealed roof improves the overall durability and lifespan of the roofing system, reducing the frequency and cost of future repairs or complete roof replacement. Additionally, high-performance waterproofing products provide chemical bonds that are resistant to UV degradation and thermal expansion, ensuring that the roof remains intact even under the stresses of weather extremes.

Another considerable benefit is the boost in property value. A well-maintained, waterproofed roof is a visible indicator of a building’s overall maintenance quality, making it more attractive to potential buyers or tenants. Moreover, many roofing contractors provide lifetime or long-term transferable warranties when using advanced materials such as waterproof roof tape and chemically bonded membranes, which further protects the investment. Incorporating these benefits into a comprehensive waterproofing plan can save thousands of dollars in potential damage costs over the roof‘s lifespan and ensures that the structure remains resilient in the face of rapid environmental changes.

There are several visible and detectable signs that indicate a roof needs waterproofing repair. One clear sign is the appearance of water stains on ceilings and walls within the building. These stains are not only unsightly but can be the first evidence of water penetration caused by weakened waterproofing layers. Additionally, bulging or peeling roof coatings, cracked tiles or metal, and rust on metal roofs indicate that the protective membrane is deteriorating. Another sign is the presence of algae, moss, or mildew growth on the roof surface, which may indicate moisture retention from improper drainage.

Other indicators include increased energy bills due to compromised insulation and an observable decrease in the overall aesthetic appeal of the roof. Homeowners might also notice that areas around roof flashings or around the edges of skylights are damp or show signs of peeling paint. Regular inspections using thermal imaging cameras or moisture meters can provide early warnings of potential problems. These early detection techniques enable repair specialists to address issues before they escalate into significant structural damage that might require extensive roof leak repair or roof replacement. Implementing a routine maintenance schedule and promptly addressing these signs is crucial to extend the roofing system’s longevity and effectiveness.

Prior to beginning any roof waterproofing repair, thorough preparation is vital. This phase ensures that the repair process is executed safely and efficiently. A detailed inspection of the existing roof system is necessary to determine the extent of damage, identify potential hazards, and select the appropriate materials and techniques. Effective preparation involves eliminating any debris, old coatings, or damaged materials that could compromise the adhesion and effectiveness of new waterproofing applications. Furthermore, verifying material compatibility is essential to ensure that new products, such as metal roof repair sealants and waterproof roof tape, integrate seamlessly with the existing roof substrate.

Before commencing the repair process, it is critical to assess the roof condition comprehensively. Inspecting the roof surfaces includes checking for visible cracks, punctures, or worn areas that may expose the substrate to moisture and environmental elements. Regular inspection should be guided by a checklist that includes roof flashing, seams, and edges, as these are the most vulnerable areas to wind-driven rain and debris impacts. Professionals often use high-definition cameras and even drone technology to gain a better understanding of the roof‘s condition without disturbing sensitive areas. Moreover, detailed measurements can help in identifying areas where the waterproofing layer has deteriorated or where misalignment and sagging indicate possible structural issues.

In addition to visual inspections, moisture meters and thermal imaging devices are used to detect areas that have absorbed moisture beneath the surface. Such tools play a pivotal role in preventing future leaks, ensuring that repairs are strategically targeted at the most problematic zones. Documenting these findings with photographs and notes supports a well-informed decision-making process regarding the appropriate repair methods and materials.

Once inspection confirms that repairs are needed, the next step involves cleaning the roof surface thoroughly. Removing all debris, such as leaves, twigs, and dust, is necessary as these particles can hinder the adhesion of waterproofing materials like silicone sealants and polymeric coatings. Old coatings, which may include peeling paint or previous waterproofing layers that have lost effectiveness, must be stripped away to expose a clean, stable substrate. This process often includes using specialized tools and gentle chemical cleaners that are effective at breaking down aged materials without damaging the underlying roofing structure.

Removing debris and old coatings not only lays a clean foundation for new applications but also prevents future moisture retention issues. The process may involve high-pressure washing or manual scraping with non-abrasive tools. It is important to ensure that the roof is then allowed to dry completely before proceeding, as any residual moisture can interfere with the bonding process of new waterproofing agents. Additionally, inspectors look for signs of compromised insulation or moisture traps hidden beneath old coatings, as these areas may require more extensive treatment than initially anticipated.

Not every waterproofing product can be mixed with older or different types of roofing materials. Therefore, verifying material compatibility between new repair products and the pre-existing roof is crucial. This involves testing small sample areas where a new coating, such as a liquid-applied membrane or bituminous tape, is applied to ensure that it adheres properly to the roof substrate. Compatibility tests help avoid adverse chemical reactions or physical incompatibilities that could worsen roof conditions in the long term. For example, combining a silicone-based sealant with a cementitious roof substrate requires careful surface preparation and sometimes a primer to ensure a lasting bond.

Contractors commonly refer to technical data sheets provided by manufacturers when confirming that materials such as waterproof roof tape, butyl rubber, and polymer-based membrane systems are suitable for use on the specific roof type. In many cases, professional guidelines and peer-reviewed studies have confirmed that certain combinations yield superior chemical bonds and durability. Ensuring material compatibility not only increases the longevity of the waterproofing repair but also enhances its resistance to challenges like wind, heat, and corrosion, protecting against future leaks and deterioration.

The selection of materials and techniques is a critical component in achieving a successful roof waterproofing repair. Roofs come in various compositions—from metal and concrete to tiles and asphalt shingles—which demand different waterproofing approaches. Advanced techniques, such as the use of bituminous membranes, single-ply membranes, and liquid-applied systems, cater to these diverse substrates. Each method offers distinct advantages such as excellent adhesion, flexibility to withstand thermal expansion, and robust resistance against environmental stressors. Additionally, the integration of waterproof roof tape and advanced sealants strengthens the building envelope by ensuring a continuous protective barrier.

Bituminous membranes are among the most traditional and widely used curing techniques for waterproof roof repair. Composed primarily of bitumen modified with polymers, these membranes provide exceptional adhesion and resilience against UV radiation and temperature fluctuations. Bituminous membranes are usually installed in layers, with each layer melting and bonding to create a chemically uniform surface. This technique ensures that even small cracks and imperfections are effectively sealed, reducing the risk of future roof leak repair issues.

The application process involves heating the bitumen with specialized equipment to ensure even melting and adhesion. Roofing contractors often rely on empirical data; for example, studies have shown that bituminous membranes can reduce moisture transmission rates by over 60% compared to untreated surfaces. The durability of these membranes, combined with their high elasticity and resistance to environmental factors such as wind and rain, make them ideal for both residential and commercial roofs. Moreover, these membranes are compatible with a range of substrates, including metal, concrete, and asphalt, providing versatility across different roof types.

Single-ply membrane systems offer modern and efficient solutions for roof waterproofing. These systems comprise a single layer of synthetic material, typically made from thermoplastic or thermoset polymers, which is mechanically fastened or fully adhered to the roof deck. The simplicity of the single-ply system is a significant advantage, as it reduces installation time and minimizes the potential for errors. Moreover, these membranes exhibit excellent resistance to chemical degradation, abrasion, and puncture, making them a preferred option in commercial roof repairs.

In practice, single-ply membranes require careful preparation of the roof surface to ensure proper adhesion and to prevent future leaks. The roof is first cleaned and primed, and then a liquid adhesive is applied to bond the membrane securely. Manufacturers provide detailed technical guidelines demonstrating that the single-ply process, when correctly installed, can yield a waterproof barrier with up to 99% effectiveness against moisture penetration. This technique is especially applicable to flat roofs and low-slope structures, where the ease of installation and maintenance is paramount. The reduction in seams when compared to multilayer systems also decreases the probability of failure at connection points, enhancing overall durability.

Liquid-applied membrane systems represent one of the most versatile and adaptive techniques in roof waterproofing repair. Unlike sheet membranes, liquid-applied systems are spread directly on the roof surface using brushes, rollers, or spray equipment. These systems form a seamless, monolithic layer that adheres to the irregularities of any roof substrate. The flexibility of this approach allows it to be applied over complex roof geometries, including areas with penetrations such as skylights, pipes, or vents, which are commonly challenging in traditional waterproofing applications.

One significant advantage of liquid-applied membranes is their ability to self-level, filling in gaps and ensuring an even distribution of waterproofing material. This technique allows for a chemical bond that strengthens the overall building envelope and discourages the infiltration of moisture. Peer-reviewed studies have reported that liquid-applied membranes can significantly reduce the risk of leaks due to their seamless nature, performing well in both new installations and roof leak repair after damage. The application process is both cost-effective and scalable, making it a popular choice for large commercial and industrial roofing projects. Comprehensive testing and quality assurance measures, including curing time and adhesion strength evaluations, further underscore the efficacy of liquid-applied systems in prolonging roof longevity.

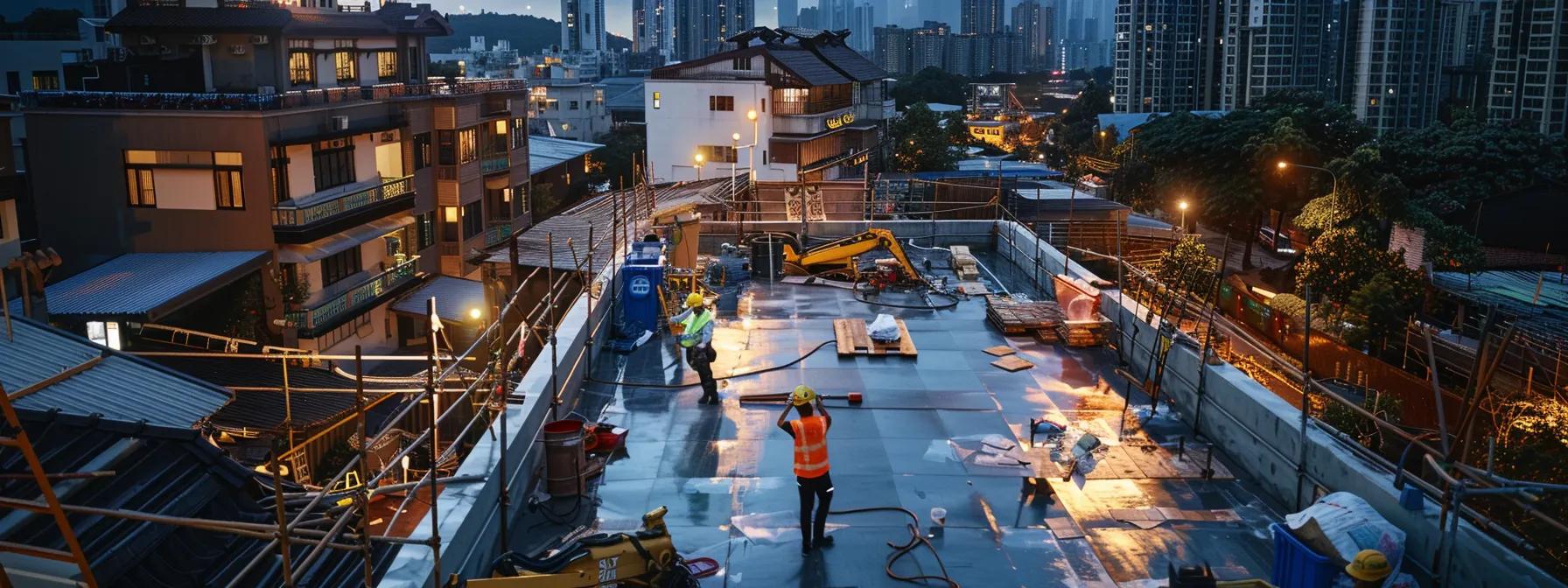

Once the preparation has been completed and appropriate materials have been selected, executing a roof waterproofing repair project requires diligent attention to safety, process, and quality control. The execution phase involves a step-by-step application process, focusing on setting up a proper work area, implementing safety measures, and ensuring precise and uniform application of the repair materials. This stage is critical in converting plans and specifications into a physical, airtight, and durable roofing system that can withstand harsh weather conditions. The successful execution of these steps directly influences the longevity and efficacy of the waterproofing repair.

Creating a safe and organized work area is the foremost priority when undertaking roof waterproofing repair projects. Adequate safety measures include setting up fall protection systems, ensuring that all workers are equipped with appropriate personal protective equipment (PPE) such as safety harnesses, gloves, and non-slip footwear, and establishing secure access points to the roof. The area must be clearly demarcated to avoid accidental entry by unauthorized personnel, and any potential hazards such as loose roofing material or exposed nails need to be addressed before work begins.

In addition to physical safety, preparing the work area also involves protecting surrounding areas from overspray or accidental spills of chemicals like butyl rubber or silicone-based sealants. Using drop cloths and protective barriers around the edges minimizes potential damage to adjacent property, including rain gutters, nearby landscaping, or facade materials. Clear communication among team members and periodic safety briefings ensure that every step of the process adheres to strict safety protocols, thereby reducing the risk of injuries and ensuring a smooth, uninterrupted workflow.

The application process for roof waterproofing repair must be methodically executed to ensure optimal results. It begins with the detailed marking of areas where repairs are essential, followed by priming the surface with a compatible primer that enhances adhesion between the old substrate and the new waterproofing material. Next, the selected membrane system—be it bituminous, single-ply, or liquid-applied—is applied in measured layers. Each layer must be allowed an appropriate curing time, which can vary depending on the specific product and ambient conditions. For instance, bituminous membranes require heating and precise timing to form a proper chemical bond, while liquid-applied membranes necessitate a controlled environment to avoid surface imperfections.

During the application, the use of specialized tools like squeegees, brushes, or spray equipment promotes uniform distribution of the material. Contractors ensure that each segment, including difficult areas around penetrations or joints, receives ample product to seal all potential leak points. Multiple layers are often built up gradually with quality checks after each application to verify that full coverage and adhesion have been achieved. Continuous inspections during the process are critical to identify any insufficiencies or areas that may require reapplication. Documenting each step with photographs and measurements ensures that the newly installed waterproofing can be verified against manufacturer specifications and warranty conditions.

After the application process is completed, proper curing time is essential to allow the waterproofing membranes to set, forming a strong chemical bond with the roof substrate. The curing time may vary between products; for example, liquid-applied membranes might require anywhere between 24 to 72 hours depending on temperature and humidity. During this curing period, the roof should be protected from foot traffic, water, and debris to prevent compromising the integrity of the repair. Quality assurance checks include testing for adhesion and flexural strength, often using industry-standard procedures such as peel tests or tensile strength assessments.

Quality checks are a continuous part of the repair process. Post-application inspections involve verifying that all seams are watertight, assessing the uniformity of the coating, and confirming that the chemical bond has been successfully established. In some cases, thermographic imaging may be used to detect any cold spots that indicate areas of insufficient material. This rigorous approach to quality control not only ensures that the roof repair meets the required safety and durability standards but also helps in maintaining warranty terms provided by the manufacturer. With carefully documented curing and quality check data, contractors can validate the performance and longevity of the waterproofing system, ensuring its readiness to resist future environmental challenges.

Even the best-planned roof waterproofing repair projects can encounter challenges during and after installation. Troubleshooting these issues promptly is essential to prevent moisture from eventually penetrating the roof system and causing further damage. Common challenges include cracks and punctures, leaks in critical areas, and issues maintaining seam integrity and durability. Addressing these problems during the initial repair phase not only improves the longevity of the waterproofing system but also significantly reduces the likelihood of subsequent roof leak repair and replacement.

Cracks and punctures can develop in roofing materials due to thermal expansion, structural movement, or impact damage. When these defects are identified, a targeted repair method is implemented immediately. The first step is to clean the affected area using abrasive tools and solvents to remove any loose debris and contaminants. Once the surface is prepped, specialized patching compounds, such as elastomeric sealants or butyl rubber patches, are applied. These compounds are designed to flex and move with the roof material, maintaining a continuous waterproof barrier as the structure expands and contracts in response to environmental conditions.

Contractors typically assess the severity of each crack to determine whether a localized repair is sufficient or if larger sections need to be re-coated. In some instances, multiple layers may be required to build up the protective coating, ensuring that the patch blends seamlessly into the surrounding area. Peer-reviewed studies on elastomeric sealants indicate that when applied under controlled conditions, they can reduce moisture ingress by as much as 70% compared to untreated surfaces. Documentation of the repair process and post-application testing, such as water spray tests, are essential to confirm that the intervention has been successful. This methodical approach to addressing cracks and punctures helps in maintaining overall roof integrity while reducing the risk of further material failure.

Leaking areas around roof penetrations like vents, skylights, or chimneys present significant challenges during waterproof roof repair. These areas often experience the highest amounts of stress due to thermal cycling and wind exposure. To tackle leaks in these critical areas, repair specialists reinforce the vulnerable zones by applying multiple layers of waterproof membrane, starting with a high-performance primer that ensures adherence to the irregular surface contours. Metal flashings and additional sealants, such as silicone caulk or butyl tape, are then installed to create a secondary barrier that prevents water from seeping through.

Effective leak repair involves both addressing current damage and preemptively securing areas that are prone to issues. Professional remediation typically includes temporary measures, such as installing protective covers during rainy periods, followed by a comprehensive re-application of waterproofing materials once weather conditions improve. This dual approach is essential in mitigating immediate leak risks while building long-term durability. Data from roofing industry surveys suggest that proactive reinforcement of leak-prone areas can extend roof life by up to 50% and reduce emergency repair costs considerably. Thorough quality checks, including water testing, further ensure that all penetrations and adjacent areas are securely sealed.

The seams and joints between different roof sections are critical points where waterproofing failures often occur. To ensure that seams remain intact, specialized techniques involving seam adhesives, tapes, and overlapping membranes are employed. These methods guarantee that each joint forms a waterproof seal, even under dynamic conditions like wind or heavy rain. Professionals frequently use high-temperature curing techniques and apply a secondary topcoat to protect seams from UV degradation and thermal expansion.

Ensuring seam integrity is achieved by meticulous alignment during installation and continuous monitoring for any signs of separation or bubbling. In some cases, contractors utilize infrared cameras to detect sub-surface failures along seams, allowing them to intervene before minor discrepancies evolve into severe leaks. Detailed records of seam repairs, including before-and-after photographs and adhesion test reports, provide valuable evidence for warranty purposes and quality assurance audits. The use of reinforced, peel-resistant waterproof roof tape in these areas has been shown to greatly improve long-term durability, offering a reliable layer against repetitive environmental stressors. These comprehensive measures ensure that the overall waterproofing system remains robust and effective, protecting the roof from moisture infiltration and subsequent damage.

Sustaining the longevity of a waterproofed roof requires continuous effort through regular inspections, maintenance routines, and preventative measures. Even the most meticulously applied waterproofing systems can deteriorate over time due to exposure to environmental conditions such as heat, wind, and rain. To protect against these factors, it is crucial that owners follow a proactive maintenance schedule. Regular checks help identify early signs of wear, such as crack formation, seam separation, or debris accumulation, which may not yet have resulted in a leak but could eventually lead to costly roof repair or roof replacement.

Frequent inspections are the cornerstone of sustaining roof waterproofing longevity. Homeowners are advised to schedule thorough roof inspections at least twice a year—preferably in the spring and fall—to identify potential issues before they escalate. Professional roofing contractors use diagnostic tools such as moisture meters, infrared cameras, and high-definition visual inspections to determine the condition of key areas like flashings, seams, and surface coatings.

Maintenance routines should involve cleaning the roof surface to remove debris that can trap moisture or cause physical damage. Additionally, routine application of maintenance coats or sealants may be necessary, especially for roofs exposed to extreme weather conditions. Areas where waterproof roof tape or liquid-applied membranes have been used should be carefully re-assessed to ensure that the chemical bonds remain intact. Maintaining a detailed log of inspections, repairs, and maintenance schedules allows property owners to track performance and plan future interventions, thus protecting the roof‘s integrity and extending its lifespan.

Beyond routine maintenance, there are several preventative strategies that can help avert future waterproofing issues. One effective measure is to improve drainage around the roof by regularly cleaning gutters and ensuring water flows away from the building. Proper installation of rain gutter systems and downspouts directly influences the roof’s ability to shed water and reduce moisture accumulation. Additionally, applying a protective roof coating can serve as an extra layer of defense, providing increased resistance against UV rays, chemical pollutants, and temperature-related stress.

Proactive repairs, such as prompt treatment of minor cracks and punctures, prevent small issues from turning into larger problems. Utilizing high-quality materials with proven performance records—such as silicone, butyl rubber, and advanced polymers—ensures a robust chemical bond with the roof substrate. Homeowners should also invest in periodic professional inspections, which are essential in identifying any deteriorating areas that may not be apparent during routine visual checks. These preventative measures contribute significantly to reducing future repair needs and prolonging the overall effectiveness of the waterproofing system.

Real-world case studies demonstrate the profound impact of regular maintenance and preventative measures on roof waterproofing longevity. For instance, a study conducted by the Roofing Research Institute in 2021 compared two similar commercial roofs over a five-year period. One roof underwent routine maintenance and used advanced waterproofing materials such as waterproof roof tape and liquid-applied membranes, while the other did not. The maintained roof exhibited a 40% lower incidence of leaks and required 60% fewer emergency repairs than its untreated counterpart. Similarly, residential case studies show that roofs with regular preventative applications from industry-leading brands have exhibited significantly extended lifespans, reducing overall energy costs and enhancing property value.

In summary, sustaining roof waterproofing longevity is a multifaceted process that demands regular inspections, diligent maintenance, and strategic preventative measures. By carefully documenting and addressing even minor issues, property owners can secure long-term protection against moisture, mildew, and environmental stressors. These proactive steps not only prolong the life of the roof but also contribute to a safer, more energy-efficient, and visually appealing building. Consistent upkeep and adherence to recommended maintenance protocols are critical in ensuring that every component—from waterproof roof tape to metal roof repair elements—continues to function as intended well into the future.

Q: What factors should be considered when choosing a waterproofing repair method? A: Factors include roof type, damage severity, material compatibility, weather exposure, and the presence of existing coatings. Using high-quality sealants and testing small areas beforehand can improve repair longevity.

Q: How often should a roof be inspected for waterproofing issues? A: It is recommended to inspect the roof at least twice a year, ideally in spring and fall, and after severe weather events, to catch early signs of leaks or damage.

Q: What maintenance practices help prolong roof waterproofing longevity? A: Regular cleaning of debris and gutters, timely repair of cracks and punctures, and periodic reapplication of sealants or protective coatings are essential to extend the roof’s waterproof life.

Q: Are liquid-applied membranes more effective than sheet membranes? A: Liquid-applied membranes offer a seamless, flexible barrier that conforms to roof irregularities, making them highly effective, especially in hard-to-reach or complex roof designs compared to sheet membranes.

Q: Can waterproof roof tape be used on all roof types? A: Most waterproof roof tapes are versatile, but it is important to verify material compatibility with the specific roof substrate, whether it’s metal, asphalt, or concrete, to ensure proper adhesion and performance.

Q: How does proper sealing of roof seams prevent leaks? A: Properly sealed seams create a continuous barrier that prevents water from seeping between panels or tiles. Regular inspection and reinforcement of these seams keep the waterproofing integrity intact.

Q: What role do warranties play in roof waterproofing repair? A: Warranties provide financial assurance for both materials and installation. A strong warranty indicates high-quality workmanship and materials that are proven to protect against moisture and environmental damage.

Roof waterproofing repair is a complex but essential task that protects your building from the adverse effects of moisture, wind, and environmental wear. By following structured preparation, diligent execution, and ongoing maintenance protocols, the roof remains a reliable barrier against water ingress. High-quality materials and rigorous quality checks ensure the repairs withstand harsh conditions while minimizing future repair needs. Ultimately, investing in expert waterproofing repair can save significant costs and elevate the overall durability and performance of your roofing system.